Any norm, convention, requirement or regulation decided as valid and fundamental in respective field are called standards.

In essence, a standard is an agreed way of doing something. It could be about making a product, managing a process, delivering a service or supplying materials – standards can cover a huge range of activities undertaken by organizations and used by their customers.

A standards organization, standards body, standards developing organization (SDO), or standards setting organization (SSO) is any organization whose primary activities are developing, coordinating, promulgating, revising, amending, reissuing, interpreting, or otherwise producing technical standards that are intended to address the needs of some relatively wide base of affected adopters.

Specification may refer to an explicit set of requirements to be satisfied by a material, design, product, or service.

In engineering, manufacturing, and business, it is vital for suppliers, purchasers, and users of materials, products, or services to understand and agree upon all requirements. A specification is a type of a standard which is often referenced by a contract or procurement document. It provides the necessary details about the specific requirements.

Specifications may be written by government agencies, standards organizations (ASTM, ISO, CEN, DoD, etc.), trade associations, corporations, and others.

Some Abbreviations of standards are as follows

1. ISO: International organization for Standards

2. ASTM: American Society for Testing and Materials

3. BSI: British Standard Incorporation

4. ISI: Indian Standards Institution

5. BIS: Bureau of Indian Standard

6. DIN: Deutsches Institution for Normum (German Institute for Standardization)

7. ANSI: American National Standards Institute

more info: http://en.wikipedia.org/wiki/List_of_technical_standard_organisations

Tuesday, December 31, 2013

Thursday, October 17, 2013

Supply Chain Management : Defination

Supply Chain: My definition of supply chain can be briefly explained as follows

- Supply chain is simply the multi-staged bidirectional movement of various entities from a resource to consumer.

- The resource-consumer at different stages are different like supplier-manufacturer, manufacturer-distributer, distributor-end user, factory-warehouse etc.

- The entities includes

- physical material (Raw material, WIP, Finished goods, defective goods, waste material, tools and equipment, packaging material etc.)

- Financial aids like material cost, credit, payments, ownership

- Information like schedules, delivery status, material tracking etc.

- Transportation and Logistic, production / assembly lines (material movement related entities)

Saturday, October 5, 2013

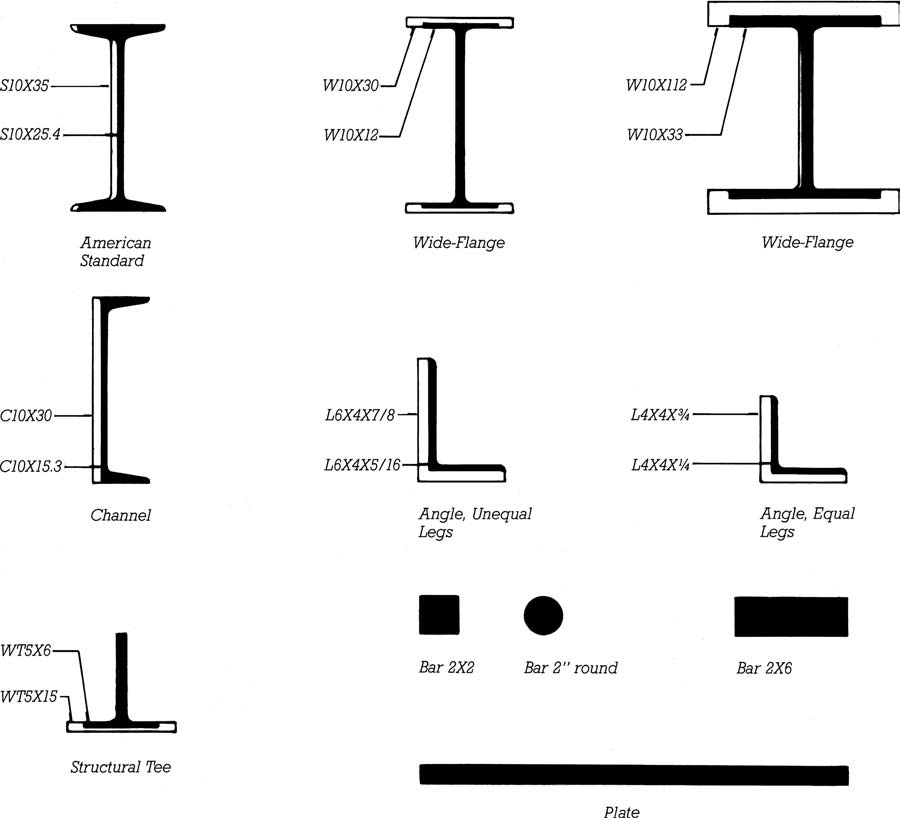

Structural Steel

Steel profiles shaped into various sections and generally used in constructions. The common shapes are as follows

1. I section (Beam)

2. C section (Channel)

3. L section (Angle)

4. T section (Tee)

5. Square/Rectangular section (Bar)

6. Round/Circular section (Rod)

7. Plate

In addition to this there are some more shapes like Hollow Structural Section (HSS), Joist, Hexagonal Section, Half Round, Oval or Elliptical, Champfer, Z-section, Asymmetrical I Section etc.

They are normally alloys of Mild Carbon Steels with Specific gravity 7.861 gm/m^3

(density = mass / volume)

1. I section (Beam)

2. C section (Channel)

3. L section (Angle)

4. T section (Tee)

5. Square/Rectangular section (Bar)

6. Round/Circular section (Rod)

7. Plate

In addition to this there are some more shapes like Hollow Structural Section (HSS), Joist, Hexagonal Section, Half Round, Oval or Elliptical, Champfer, Z-section, Asymmetrical I Section etc.

They are normally alloys of Mild Carbon Steels with Specific gravity 7.861 gm/m^3

(density = mass / volume)

Subscribe to:

Comments (Atom)